Welcome To Subscribe To Our Product Information

Learn More About Our Products

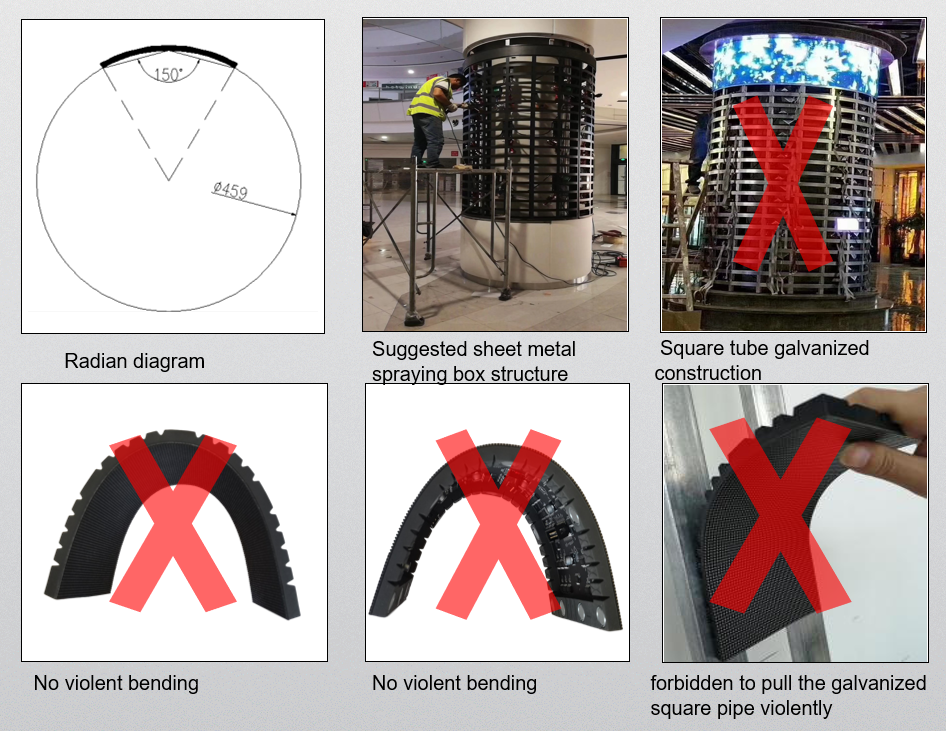

How to assemble and install soft flexible LED module display

![]() 2022-04-06

2022-04-06

![]() hypervision

hypervision ![]() 1324

1324

The PCB of flexible led module display is super soft and the user should be carefully when assemble the modules.